Short answer: Fitout coordination with MEP in Qatar is the process of aligning interior layouts, ceilings, finishes, and joinery with mechanical, electrical, and plumbing services before and during execution. Most site conflicts occur when this coordination is incomplete, leading to clashes, rework, and delayed inspections.

What Is Fitout MEP Coordination In Qatar

Fitout MEP coordination in Qatar refers to the alignment of interior design elements with mechanical, electrical, and plumbing services to ensure buildability and functionality.

This coordination links fitout documentation with MEP layouts so that ceilings, partitions, lighting, diffusers, and access panels can be installed without conflict.

Why Most Site Conflicts Start With MEP

In Qatar fitout projects, MEP services occupy shared ceiling and wall zones where space is limited.

When coordination is incomplete, services clash with interior elements, forcing last-minute changes during execution.

Common Fitout MEP Conflicts In Qatar

Most coordination issues arise from misalignment between fitout and MEP drawings.

| Conflict Area | Typical Issue | Impact On Site |

|---|---|---|

| Ceilings | Insufficient space for services | Ceiling level changes |

| Lighting And Diffusers | Overlapping locations | Repositioning works |

| Partitions | Services passing through walls | Rework and fire issues |

| Access Panels | Missing maintenance access | Inspection failures |

Coordination Between Fitout And MEP Drawings

Effective coordination requires that fitout and MEP drawings are reviewed together, not in isolation.

This review typically occurs before execution and is verified continuously through site supervision.

Where Coordination Breaks Down On Site

Coordination breakdowns often occur when drawing updates are not communicated or when sequencing is rushed.

These issues are frequently discovered during inspections or recorded later in the snagging stage.

Fitout MEP Coordination Workflow

Effective fitout coordination with MEP in Qatar follows a defined workflow that aligns drawings, sequencing, and site execution before conflicts occur.

| Stage | Coordination Activity | Risk If Skipped |

|---|---|---|

| Design Coordination | Overlay fitout and MEP drawings | Hidden clashes |

| Ceiling Zoning | Confirm service and ceiling depths | Level changes and redesign |

| Shop Drawings | Finalize service routes and access | Execution delays |

| Site Verification | Confirm installations match drawings | Rework and inspection failure |

This workflow relies on coordinated inputs from fitout, MEP, and consultant teams rather than isolated reviews.

How Fitout MEP Clashes Are Resolved

When clashes occur, resolution typically involves trade-offs between aesthetics, performance, and maintenance access.

In Qatar projects, resolution decisions should be documented to prevent repeat conflicts.

| Clash Type | Typical Resolution | Consideration |

|---|---|---|

| Ceiling Congestion | Adjust ceiling height or service routing | Impact on aesthetics |

| Lighting And Diffusers | Relocate fixtures | Uniformity and comfort |

| Partition Interference | Re-route services or modify partitions | Fire and acoustic compliance |

Resolution effectiveness depends on timely involvement of site supervision teams.

How Proper Coordination Reduces Rework And Delays

Early and continuous coordination significantly reduces the likelihood of rework during execution.

- Fewer drawing revisions during construction

- Reduced ceiling and service modifications

- Smoother inspections and approvals

- Lower snag volumes at project completion

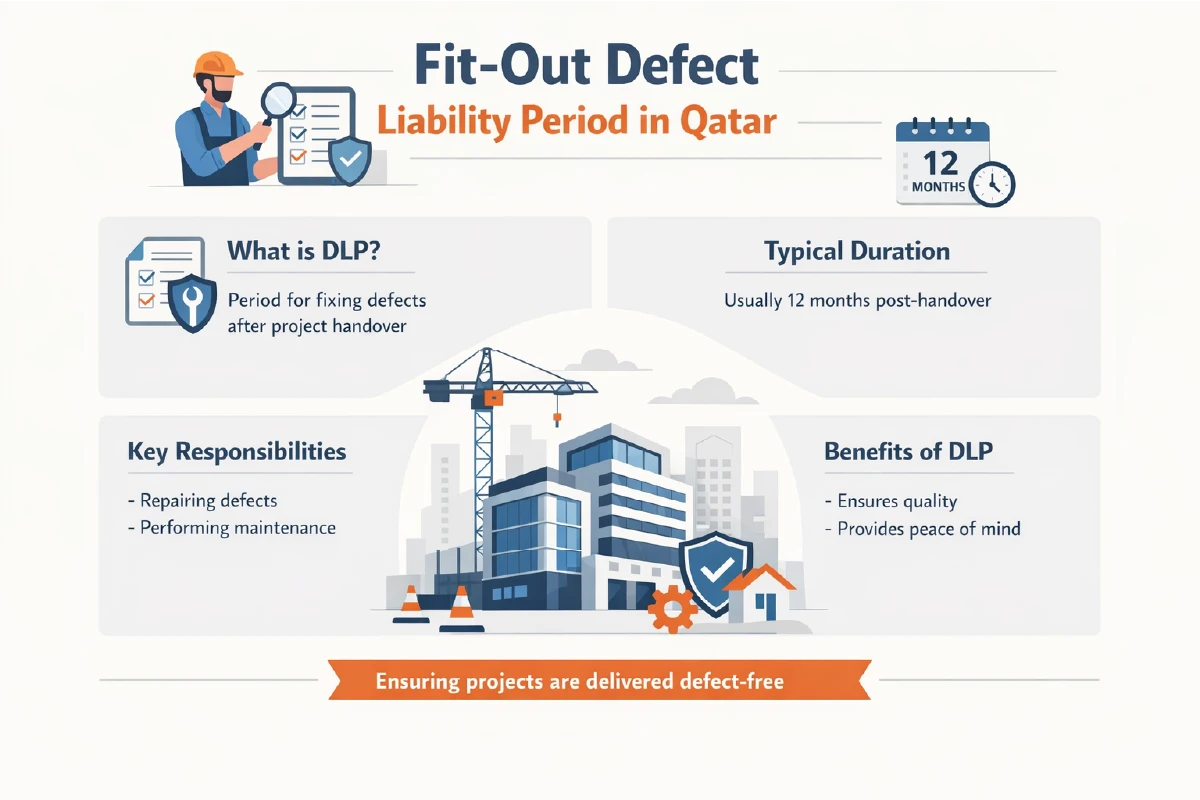

Projects with strong coordination typically experience smoother progression into handover and fewer issues during the defect liability period.

Key Takeaways

- MEP Coordination Is A Major Risk Area: Most fitout site conflicts in Qatar originate from misalignment between interior works and MEP services.

- Drawings Must Be Reviewed Together: Fitout and MEP drawings should be coordinated as a single system, not in isolation.

- Ceiling Zones Require Early Attention: Limited ceiling space is the most common source of clashes.

- Early Resolution Reduces Rework: Timely coordination minimizes execution changes and delays.

- Strong Coordination Supports Smooth Handover: Projects with effective MEP coordination face fewer snags and DLP issues.

FAQs

Is MEP Coordination Required For All Fitout Projects In Qatar

Yes. All fitout projects require some level of coordination with MEP systems, even for minor interior works.

Who Is Responsible For Fitout MEP Coordination

Coordination is typically managed by consultants or project managers, with inputs from fitout and MEP contractors.

Can Poor MEP Coordination Delay Handover

Yes. Unresolved MEP clashes often lead to inspection failures, rework, and delayed handover.

How Can MEP Conflicts Be Reduced Early

Overlaying drawings early, confirming ceiling zones, and maintaining continuous site supervision help reduce conflicts.

References

- Standard MEP and fitout coordination practices applied in Qatar commercial projects

- Common consultant-led coordination workflows used across GCC fitout executions