Short answer: A fitout snag list in Qatar is the formal record of defects, incomplete works, and quality issues identified after construction but before final acceptance. Snagging ensures that fitout works meet approved drawings, specifications, and workmanship standards before handover.

What Is A Fitout Snag List In Qatar

A fitout snag list in Qatar is a documented list of defects, omissions, or quality issues identified during inspection after construction works are substantially complete.

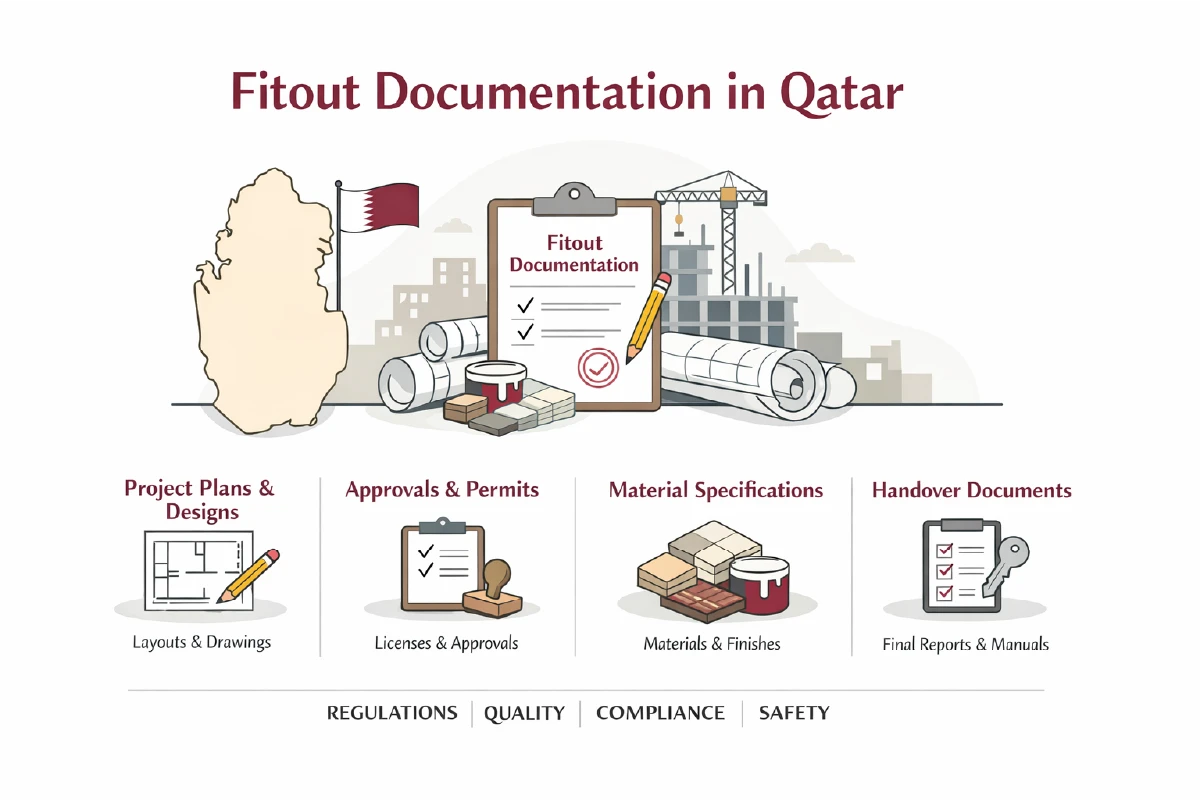

It is used to verify compliance with approved fitout documentation before final acceptance.

When Snagging Is Carried Out

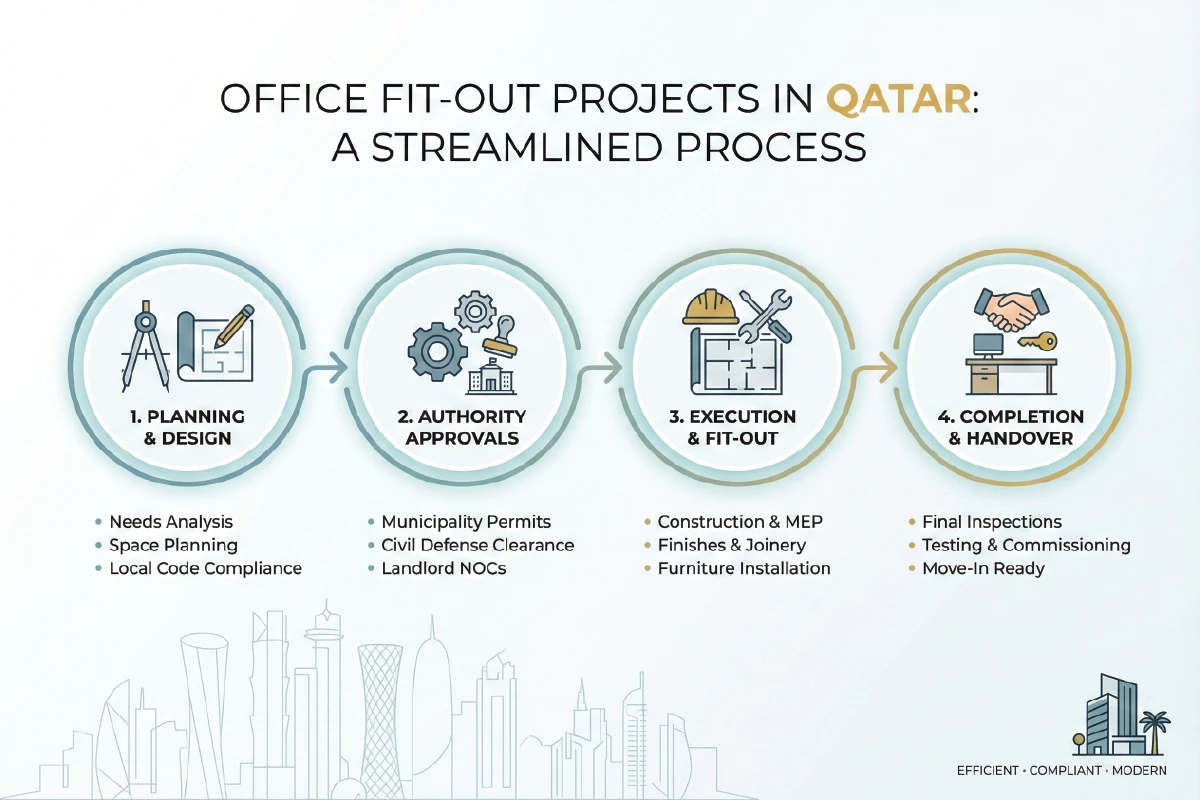

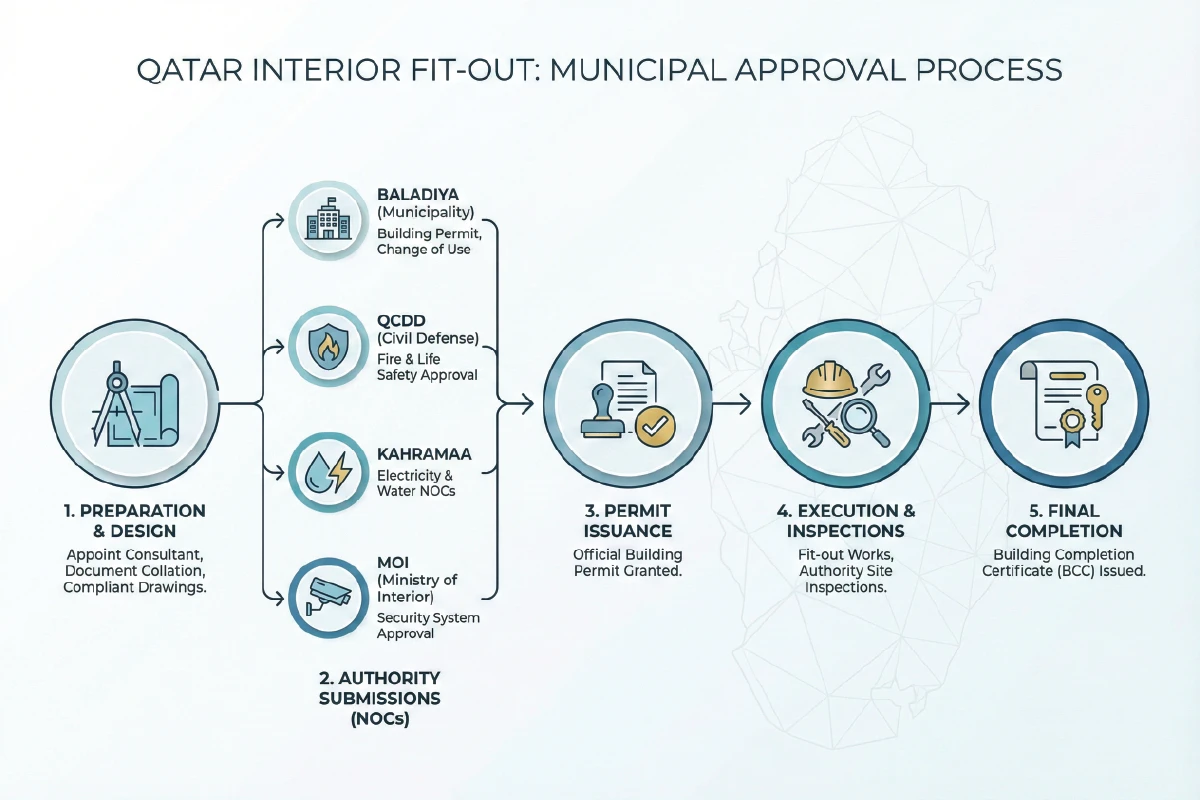

Snagging is typically carried out once fitout works are completed and services are operational, but before handover.

In Qatar projects, snagging sits between execution and fitout handover, acting as the final quality checkpoint.

Who Prepares The Snag List

Snag lists are usually prepared by consultants, client representatives, or independent inspectors.

Input from site supervision teams helps ensure that snag items are specific, measurable, and verifiable.

Common Snag Items In Qatar Fitouts

Snag items in Qatar fitout projects commonly relate to finishes, alignment, and system performance.

| Category | Typical Snag | Impact If Unresolved |

|---|---|---|

| Finishes | Uneven paint or damaged surfaces | Visible defects after occupation |

| Joinery | Misaligned doors or drawers | Operational inconvenience |

| Ceilings | Open joints or misaligned tiles | Aesthetic issues |

| MEP Systems | Non-functioning lighting or HVAC imbalance | Comfort and usability issues |

Why Snagging Is Critical

Snagging ensures that defects are corrected before responsibility shifts to the client.

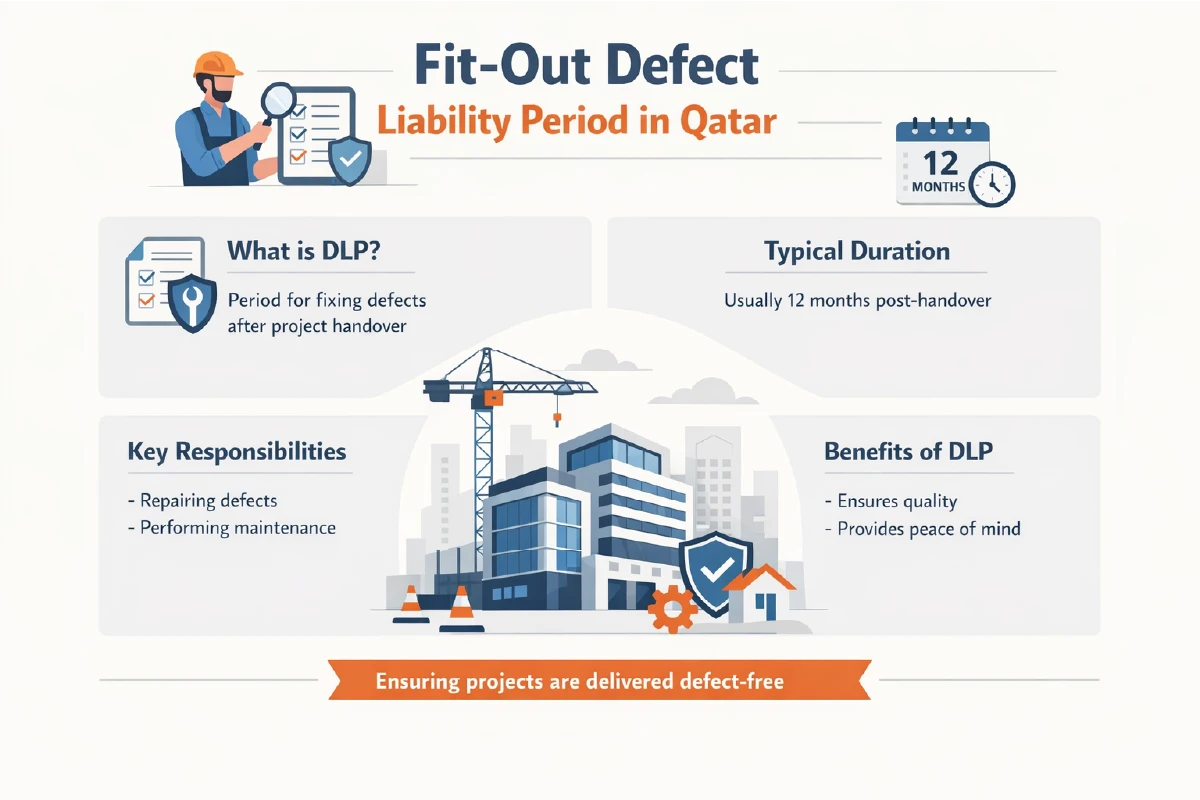

Unresolved snags often transfer into the defect liability period, increasing post-handover management effort.

Snagging Workflow And Tracking

Snagging in Qatar follows a structured workflow to ensure defects are identified, recorded, rectified, and verified before acceptance.

| Stage | Action | Responsible Party |

|---|---|---|

| Initial Inspection | Identify defects and incomplete works | Consultant or client |

| Snag List Issuance | Document and circulate snag items | Consultant |

| Rectification | Correct listed snags | Contractor |

| Reinspection | Verify closure of snags | Consultant or client |

Clear tracking prevents disputes over whether issues were raised before handover.

Rectification And Verification Process

Rectification involves correcting snag items to the approved standard, followed by verification to confirm compliance.

In Qatar projects, verification is often supported by records from site supervision and photographic evidence.

| Challenge | Cause | Impact |

|---|---|---|

| Repeated Snags | Poor workmanship | Delayed acceptance |

| Access Limitations | Occupied areas | Extended timelines |

| Material Availability | Late procurement | Partial closures |

How Snag Lists Affect Acceptance And Timelines

Completion of snag items is a key prerequisite for final acceptance in Qatar fitout projects.

Unresolved snags can delay acceptance or shift issues into the defect liability period, increasing post-handover coordination.

Projects with clear snagging processes typically experience smoother transitions into handover and occupancy.

Key Takeaways

- Snagging Is A Quality Control Step: Fitout snag lists in Qatar capture defects and incomplete works before final acceptance.

- Timing Matters: Snagging occurs after execution but before handover and should not be skipped or rushed.

- Clear Tracking Prevents Disputes: Documented snag lists help ensure accountability and timely rectification.

- Unresolved Snags Affect Acceptance: Incomplete snags can delay handover or move into the defect liability period.

- Effective Supervision Reduces Snags: Strong site supervision minimizes the number and severity of snag items.

FAQs

Who Is Responsible For Closing Snag Items In Qatar Fitout Projects

The contractor is typically responsible for rectifying snag items, while verification is carried out by the consultant or client.

Can Handover Proceed With Open Snags

Minor snags may be accepted with conditions, but significant unresolved snags usually delay final acceptance.

How Detailed Should A Fitout Snag List Be

Snag lists should be specific, measurable, and linked to drawings or locations to ensure clear rectification.

Are Snag Lists Used After Handover

Snag lists primarily apply before handover, while post-handover issues are managed under the defect liability period.

References

- Standard snagging and quality control practices used in Qatar commercial fitout projects

- Common consultant-led inspection and defect tracking methodologies